027-84841595

400-038-8928

1、 Customer requirements

Anti corrosion and derusting of steel plate surface, derusting grade Sa2.5, surface roughness ra25um.

2、 Current equipment: through shot blasting machine & sand blasting room

3、 Abrasives currently used and their effects after treatment

At present, alloy steel ball S460 is used. After treatment, the surface roughness of the workpiece is too high, and the dust can not be completely cleaned. The effect after treatment is as follows:

The derusting grade is sa2.0-2.5, the roughness is ra57-62um, and the broken rate of steel shot is relatively high.

4、 Effect after abrasive change and treatment

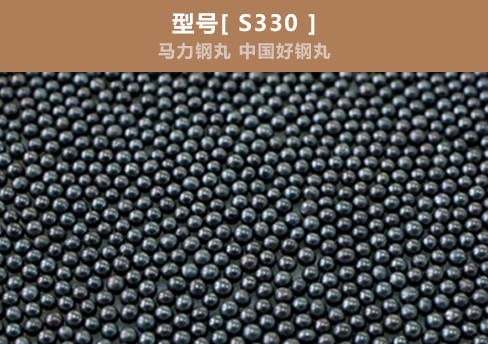

1. Use S330 alloy steel shot (secondary tempering steel shot of Hongxin steel shot)

The derusting grade is about Sa2.5, the roughness is ra40-50um, the derusting grade can meet the requirements of your company, the roughness is reduced, and the dust situation will be relieved.

Click the picture to view the product details

2. Use S230 alloy steel shot (secondary tempering steel shot of Hongxin steel shot)

The derusting grade is about sa3.0, the roughness is ra20-30um, the derusting grade can exceed the requirements of your company, the roughness can also meet the requirements of your company, and all dust conditions will be solved.

Click the picture to view the product details

Last article:Anticorrosion design scheme of shiplift in shipyard

Next article:Anticorrosion and derusting scheme of steel plate and steel pipe surface in Shangqiu, Henan Province

Contacts:Manager Chen

Tel:027-84841595

Mobile phone:13016427928

Fax:027-84841595

Address:602, unit 6, building 123, Riyueshan mountain, panlongcheng, Huangpi District, Wuhan City, Hubei Province

Hotline

027-84841595

400-038-8928