027-84841595

400-038-8928

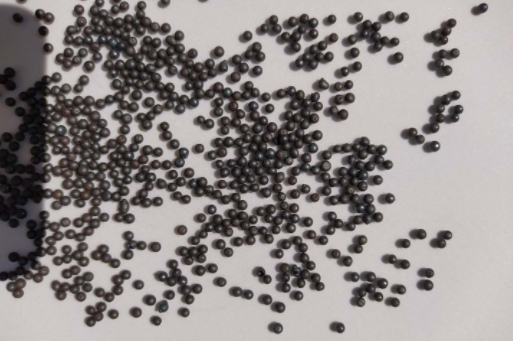

Hardness Characteristics of Steel Shots

Steel shots are spherical abrasives made of high-carbon alloy steel, with a hardness typically ranging from HRC40 to HRC50. After special heat treatment, their hardness can be increased to HRC57 to HRC62. This high hardness enables steel shots to have a longer service life during the shot blasting process and also provides stronger cleaning power. The microhardness of steel shots ranges from 390HV to 530HV, providing a clear scientific basis for their hardness.

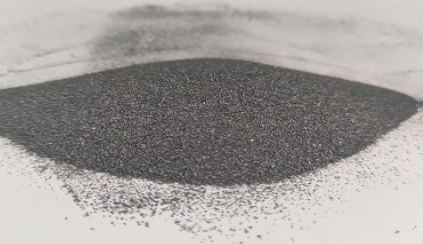

Hardness Characteristics of Steel Grits

In contrast, steel grits are irregularly shaped abrasives made of iron or steel, with a relatively lower hardness. The hardness of steel grits generally falls between HRC45 and HRC65. As steel grits are cast, their internal structure is relatively loose, resulting in lower hardness. This lower hardness leads to greater friction and poorer wear resistance during the shot blasting process.

Scientific Basis for Hardness Comparison

Hardness measures a material's ability to resist scratching by a hard object. Steel shots, after undergoing multiple heat treatments and quenching processes, have a tight internal structure and high hardness. On the other hand, due to their irregular shape and casting process, steel grits have a relatively loose internal structure, leading to lower hardness.

Application Impacts of Hardness Differences

The differences in hardness directly affect the application scenarios of steel shots and steel grits. Steel shots, with their high hardness and uniform stress distribution, are suitable for workpieces requiring high surface finish, such as automotive parts, aerospace equipment, and precision machinery. Steel grits, with their lower hardness and angular shape, are suitable for workpieces requiring high surface roughness, commonly used in shipbuilding, bridges, steel structures, pipelines, and surface treatment of large mechanical equipment.

The differences in hardness between steel shots and steel grits determine their distinct applications in industrial surface treatment. Choosing the appropriate abrasive ensures the effectiveness and efficiency of the shot blasting process, while also enhancing the service life and performance of the workpieces.

Your Most Thoughtful Expert in Anti-corrosion and Rust Removal!

Consultation Hotline: 400-038-8928

Telephone: 027-84841595

Steel Shot Sister Hotline: 13016427928

Official Website:www.malgw.com

Disclaimer: some articles and information on this website are from the Internet. The purpose of reprinting on this website for the purpose of transmitting more information and learning does not mean that we agree with their opinions or confirm the authenticity of their contents. If the reprint involves copyright and other issues, please contact online customer service or administrator immediately, and we will change or delete relevant articles to ensure your rights.

Title:What are the differences in hardness between steel shots and steel grits? website:http://malgw.com/infonews/554.html

Without permission, it is forbidden to collect and mirror all the graphic content of the website in any form, otherwise, you will be responsible for the consequences!

Last article:Differences and Applications of Steel Shot and Steel Grit

Next article:What Makes High-Quality Steel Grit?

Contacts:Manager Chen

Tel:027-84841595

Mobile phone:13016427928

Fax:027-84841595

Address:602, unit 6, building 123, Riyueshan mountain, panlongcheng, Huangpi District, Wuhan City, Hubei Province

Hotline

027-84841595

400-038-8928