027-84841595

400-038-8928

In the field of industrial manufacturing, as an important surface treatment consumable, steel shot is widely used in sandblasting, shot blasting and other processes to remove oxide scale and rust on the surface of the workpiece and improve the surface quality of the workpiece. However, there are significant differences in the cost of use between different types of steel shots, which is crucial for production decisions.

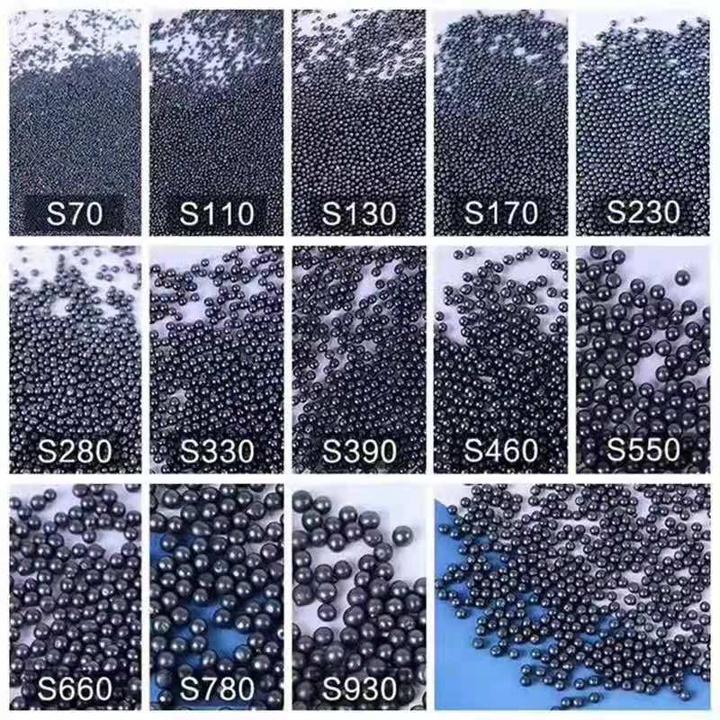

1. Classification and characteristics of steel shot models

First of all, our common steel shots are classified according to the dimensions of material, hardness, particle size, etc. For example, according to the material, it can be divided into ordinary carbon steel shots and stainless steel shots; According to the hardness, there are low hardness (HRC 40 - 50), medium hardness (HRC 50 - 60) and high hardness (HRC 60 or above); Particle sizes range from 0.2mm to 3mm. The characteristics of different types of steel shots determine their application scenarios and service life, which in turn affects the cost.

2. the procurement cost comparison

In the procurement process, the price difference between different types of steel shot is obvious. Taking ordinary carbon steel pellets as an example, the price per ton of small particle size (0.2 - 0.5mm) is about 3000 - 3500 yuan, the price of medium particle size (0.8 - 1.5mm) is 2800 - 3200 yuan, and the market price of large particle size (2 - 3mm) is about 2500 - 2800 yuan per ton due to the relatively simple production process. Stainless steel pellets, due to their high material cost, can be sold at 12,000-15,000 yuan per ton for small particle sizes, and about 10,000-12,000 yuan for large particle sizes. This is due to the cost of raw materials, the difficulty of processing and the advantages of corrosion resistance of stainless steel.

3. Service life and wear cost

The rate of wear and tear of the steel shot during use is a key factor affecting the cost. Low hardness steel shot wears out faster when dealing with the surface of a workpiece with a higher hardness. For example, when blasting an alloy steel workpiece with a hardness of HRC 55, the loss of a low-hardness shot can be 20 to 30 percent per 10 tons of workpiece, which means that new steel shots need to be replenished frequently. The loss of medium-hardness steel shot is relatively slow, about 10% - 15% of the same amount of workpiece is processed, and the loss of high-hardness steel shot can be controlled at 5% - 10%. From the perspective of long-term use, if 100 tons of workpieces of similar hardness are processed in a month, an additional 2-3 tons need to be purchased for the selection of low-hardness steel shots, and the cost will increase by 6000-9000 yuan at 3000 yuan per ton; The high-hardness steel shot only needs to be supplemented by 0.5 - 1 ton, and the cost increases by 1250 - 2500 yuan.

4. processing efficiency and energy cost

Different types of steel shots also have an impact on the processing efficiency, which in turn correlates to energy costs. Due to the large kinetic energy and wide single impact area, the large particle size steel shot has a high efficiency in the treatment of large-area and thick rust layer workpieces. For example, for large ship decks, a blast machine using 2 - 3mm shot shot can process 20 - 30 square meters per hour, while a small 0.5 - 1mm shot can only process 10 - 15 square meters per hour. However, large particle size steel shots need to be driven by more powerful equipment, and the energy cost will rise. Taking a 50kW shot blasting machine as an example, the use of large particle size steel shot consumes 50 kWh of electricity per hour, and the energy consumption cost per hour is 40 yuan based on the industrial electricity consumption of 0.8 yuan/kWh; The power of the small particle size steel shot equipment is 30kW, the power consumption is 30 kWh per hour, and the energy consumption cost is 24 yuan.

5. Comprehensive cost consideration and selection suggestions

Considering cost factors such as procurement, loss, and energy consumption, enterprises need to weigh the pros and cons when choosing a steel shot model. For general carbon steel workpieces, surface treatment requirements are not extremely high and the processing capacity is large, ordinary carbon steel shots with medium particle size and medium hardness are cost-effective, which can not only have a certain processing efficiency, but also have a relatively balanced loss and procurement cost. If you deal with high-end materials such as stainless steel and non-ferrous metals or have strict requirements for the surface quality and accuracy of the workpiece, stainless steel pellets have high procurement costs, but they have become the best with their advantages of low pollution and high precision. In areas with tight energy costs, optimizing the selection of small particle size steel shots with appropriate power equipment can reduce energy consumption expenses under the premise of first-class quality.

(Beijing Daxing National Airport)

In short, understanding the cost details of different types of steel shots will help enterprises accurately select models according to their own production needs, reduce costs and increase efficiency, and enhance market competitiveness.

Your Most Thoughtful Expert in Anti-corrosion and Rust Removal!

Consultation Hotline: 400-038-8928

Telephone: 027-84841595

Steel Shot Sister Hotline: 13016427928

Official Website:www.malgw.com

Disclaimer: some articles and information on this website are from the Internet. The purpose of reprinting on this website for the purpose of transmitting more information and learning does not mean that we agree with their opinions or confirm the authenticity of their contents. If the reprint involves copyright and other issues, please contact online customer service or administrator immediately, and we will change or delete relevant articles to ensure your rights.

Title:Cost analysis using different types of steel shots website:http://malgw.com/infonews/562.html

Without permission, it is forbidden to collect and mirror all the graphic content of the website in any form, otherwise, you will be responsible for the consequences!

Last article:Changshu Changfeng Steel Pipe Co., Ltd. won the title of Made in China Champion Enterprise

Next article:What is the size of the H-beam shot blasting and rust removal model?

Contacts:Manager Chen

Tel:027-84841595

Mobile phone:13016427928

Fax:027-84841595

Address:602, unit 6, building 123, Riyueshan mountain, panlongcheng, Huangpi District, Wuhan City, Hubei Province

Hotline

027-84841595

400-038-8928